產品中心

Products以市場為導向,注重產品的創新研發.

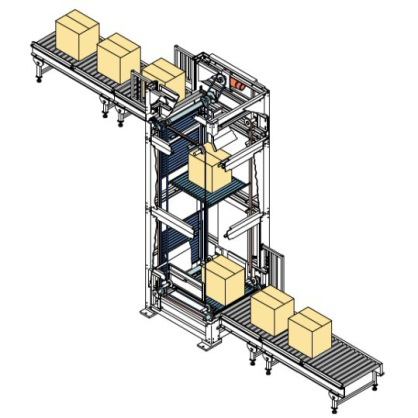

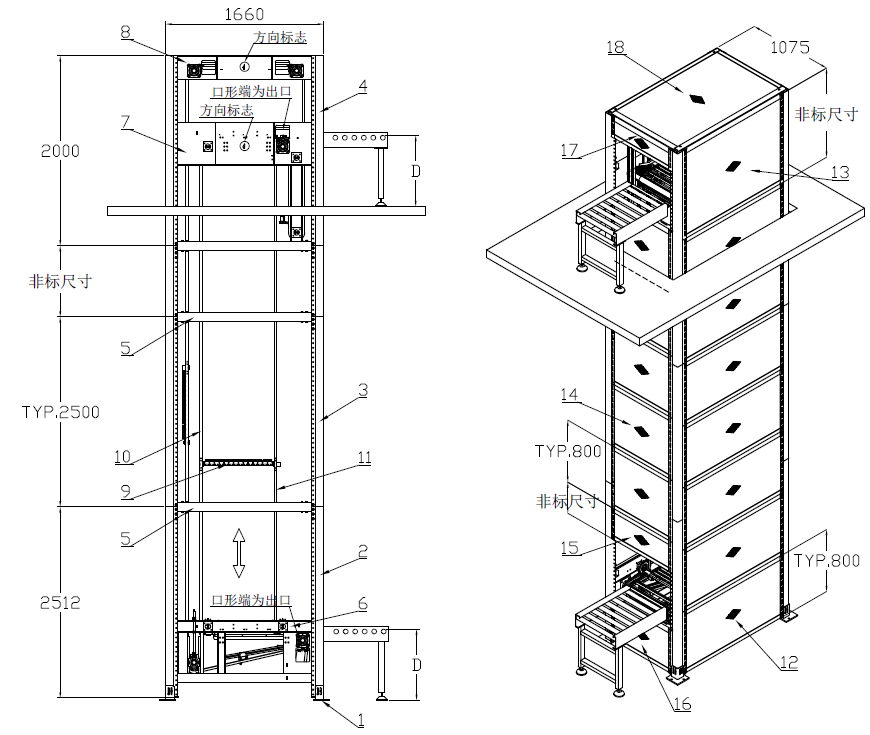

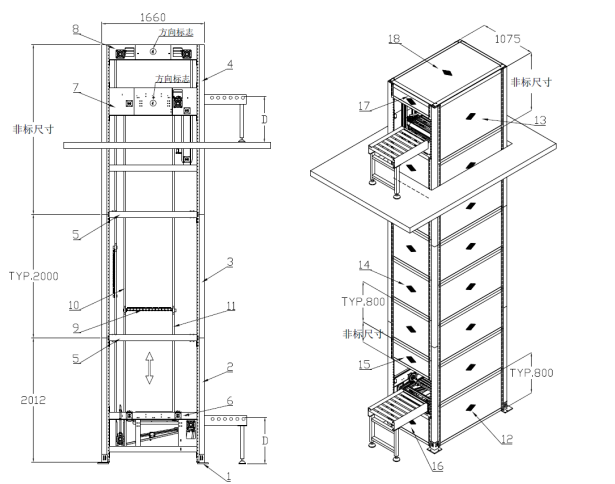

連續式提升機

連續提升機用于從水平方向向垂直方向貨物的輸送,它具有占地面積小、運行快速、安靜、安全的特點。在出入口配置輸送線能自動完成貨物的上下輸送,可用于工廠、物流中心樓上與樓下的貨物輸送。

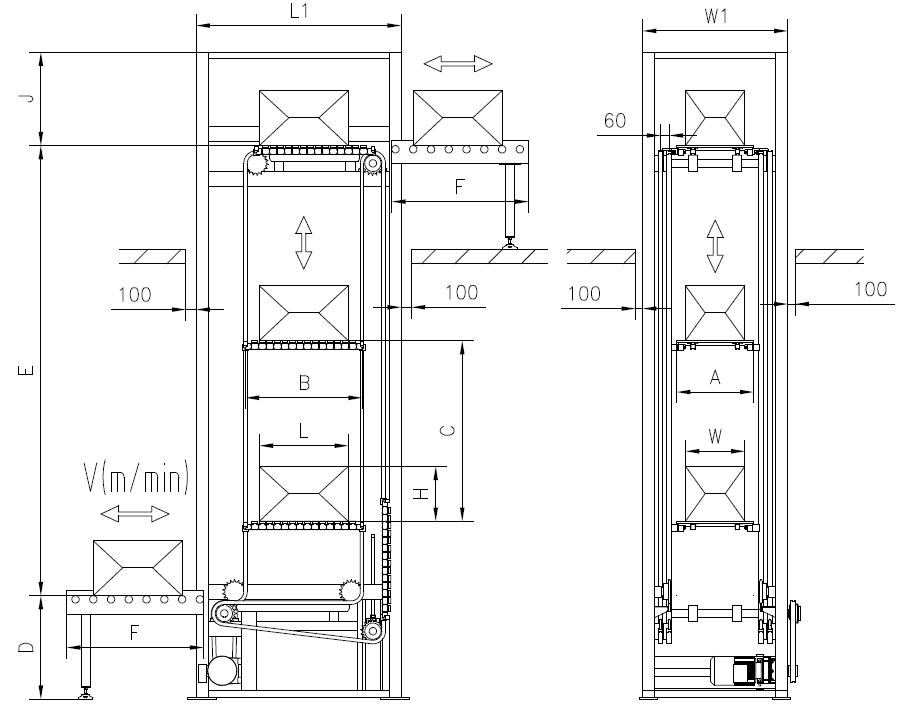

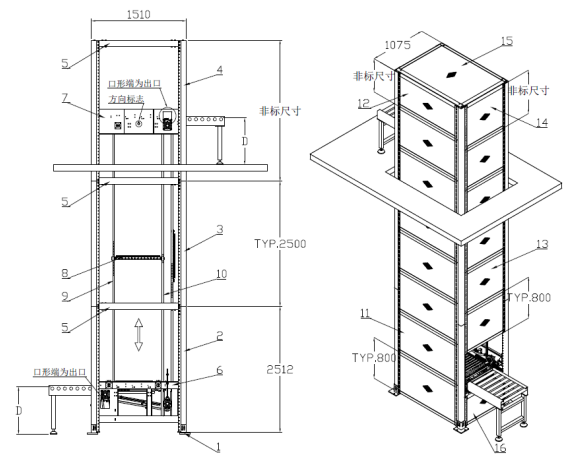

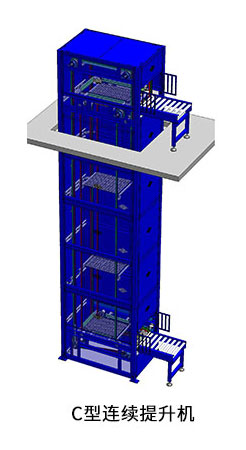

Z型提升機為“Z”字型方向輸送的提升機,即貨物從一側進入,從背面一側輸出輸送方向為從下到上。C型提升機為“C”字型方向輸送的提升機,即貨物輸送進出口為同一側輸送方向為從上到下。

連續提升機是用于對單元貨物,進行連續提升或者下降輸送的特種設備。 由于其鏈板回程不占用工作節拍和提升空間,因此具有效率高,造價低,占用空間小等特點。與螺旋鏈板機相比,它具有占地面積小、成本低。 與往復式提升機相比,它具有效率高。

適用的輸送物:塑料周轉箱、紙質包裝、工裝板以及底面具有連續承載面的硬質輸送物。

一、主要機械結構和特征:

機體:采用框架組合式結構,主要由上、中、下三部分框架組成,通過調整中間框架的數量和長度以滿足不同提升高度的需求。框架中立柱采用C型冷彎型材,單側焊接成型,然后通過螺栓連接成獨立框架。

外封框:采用鋼絲網封框。

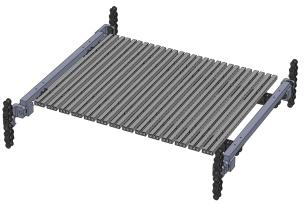

載貨臺:采用托板鏈連接鋁型材組成載貨平臺,載貨平臺配備有前后不同U型連接件,通過U型連接件連在提升鏈條上,隨著提升鏈條運行,如下圖所示:

表面涂裝:機架、安裝板等零件經鋼絲刷、砂紙等除銹,酸洗去油脂,磷化后表面靜電噴涂環氧樹脂粉末并烘烤,樹脂厚度在60μm-90μm之間。噴涂色由甲方指定色卡。

外購件配置:減速電機用SEW,鏈條用杭州東華,托板鏈用東方特種,帶座軸承用TR、軸承用哈軸。

The continuous hoist is used for conveying goods from the horizontal direction to the vertical direction. It has the characteristics of small footprint, fast operation, quiet and safety. The conveyor line is arranged at the entrance and exit to automatically complete the cargo transportation up and down, and can be used for cargo transportation in the factory and logistics center upstairs and downstairs.

The Z-type hoist is a hoist that conveys in the "Z" shape, that is, the cargo enters from one side, and the output direction from the back side is from bottom to top. The C-type hoist is a hoist that conveys in the direction of “C” shape, that is, the conveying direction of the cargo conveying inlet and outlet is from the top to the bottom.

Continuous hoists are special equipment used for continuous lifting or lowering of unit cargo. Because the chain backhaul does not occupy the working beat and the lifting space, it has the characteristics of high efficiency, low cost and small occupied space. Compared with the spiral chain machine, it has a small footprint and low cost. It is more efficient than a reciprocating hoist.

Applicable conveyors: plastic containers, paper packaging, tooling plates, and rigid conveyors with continuous load-bearing surfaces on the underside.

First, the main mechanical structure and characteristics:

The body adopts a frame combined structure, which is mainly composed of upper, middle and lower parts. The number and length of the intermediate frames are adjusted to meet the requirements of different lifting heights. The frame center column is made of C-shaped cold-formed profiles, welded on one side and then bolted into a separate frame.

Outer frame: A wire mesh frame is used.

Cargo platform: The pallet is connected with aluminum profiles to form a cargo platform. The cargo platform is equipped with different U-shaped connectors before and after. It is connected to the lifting chain through U-shaped connectors. As the chain is lifted, as shown below:

Surface coating: parts such as racks and mounting plates are rusted by wire brush, sandpaper, etc., pickled and greased, and the surface of the phosphating surface is electrostatically sprayed with epoxy powder and baked. The thickness of the resin is between 60μm and 90μm. The spray color is specified by Party A.

Purchased parts configuration: SEW for geared motor, Hangzhou Donghua for chain, Oriental special for pallet chain, TR for bearing, Harbin for bearing.